If you’re familiar with BELLA+CANVAS, you’ve probably heard of our Flowy tees and tanks collection. It’s one of our top-selling fabrications because of it’s super-soft fabric and retail appeal. Flowy is a synthetic fabric made up of 65% polyester and 35% viscose, so it takes a screen print a bit differently than your typical 100% cotton tee. This blog post and video are for you printers out there looking for tips and tricks for getting amazing results on poly-viscose fabric!

How to Screen Print Light-Colored Flowy Fabric

Have you ever felt our Flowy fabric? It’s insanely soft. When screen printing, it’s important to choose an ink that complements the drape of the the original garment, which is why water based inks are top recommendation for printing on lighter-colored garments. Water based ink saturates into the fibers of the fabric, so the resulting print won’t have any hand-feel. When working with a blank white t-shirt or garment, the colors of the print will be true to their original color. But if you’re working with a light-colored garment like our heather stone, the ink color will mix with the garment color and you’ll end up with more of a muted or vintage-looking print.

When working with poly-viscose fabric, you should use a spray adhesive before loading the garment onto the machine to avoid slippage. Another consideration is that water based ink needs to be used in lower temperatures and kept moist, which you can do by using a spray bottle to keep the ink from hardening up. Since water based ink takes longer to cure than plastisol, for instance, you may need to adjust the belt speed and temperature.

Screen print using water based ink on our heather stone 8838 Women’s Slouchy Tank

Screen print using water based ink on our white 8838 Women’s Slouchy Tank

How to Screen Print Dark-Colored Flowy Fabric

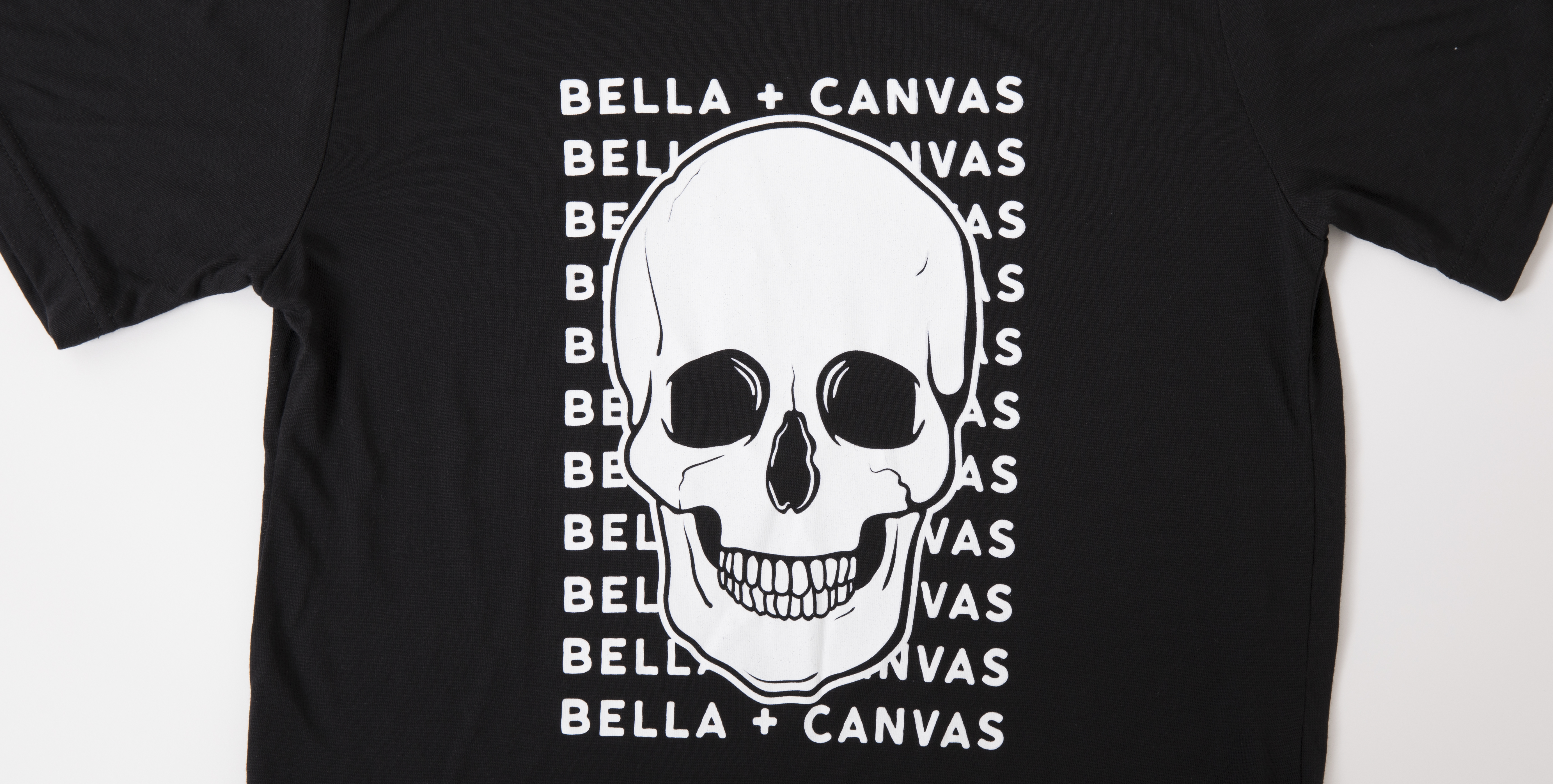

When printing on darker flowy garments, or any other fabrics that have a high polyester content, you’ll want to use a poly-blocker base to prevent any dye migration that might occur. You can do this with water based or plastisol ink, but when choosing an ink, you’ll want to take the artwork into consideration. For thinner designs, plastisol will work great, but for larger designs try to go with a water based ink.

Plastisol is great when your artwork doesn’t cover a lot of surface area. For example, if you are printing a smaller design, or something with a lot of thin lines, you won’t be adding a ton of weight to this light-weight, soft fabric. Whereas, if the print has a lot of coverage, plastisol ink will take away from the softness of the fabric. Plastisol is a great ink for beginners as it’s super easy to work with. If you’re a beginner trying to screen print on our Flowy fabric, we recommend using a plastisol ink. However, as we mentioned above, the fabric is really soft, so we only recommend plastisol ink with artwork that includes thin lines. Since our Flowy products are made up of 65% polyester, to avoid dye migration, be sure to use a poly-blocker base first. Once you lay down the base and flash it, then you can move forward as usually screen printing with plastisol.

Traditional water based ink is more transparent, so if you’re looking for a soft-hand screen print on a dark-colored poly-viscose garment, you’ll want to use a base. Since water based ink is so sensitive to work with, this technique is for more advanced screen printers. It’s a great solution for getting a soft-hand solid print on our Flowy fabric. All you need to do is find a water based poly blocker that you will lay down first. Then, after flashing, apply some spray silicone and lay down the colored water based ink on top. The base will allow the color to be vibrant, but still keep that soft hand.

Screen print using plastisol ink with poly blocker base on our 8803 Women’s Flowy Muscle Tank

Screen print using water based ink with water based poly blocker base on our 3880 Unisex Viscose Fashion Tee

Check out our video below with Deluxe Screen Printing where you can see these screen prints in action!

Did you love the designs we used in our video? They were all created by our good friend Charley Pangus. Check out his YouTube channel HERE!

2 Comments