It’s been a little over a month since we launched the industry’s first-ever Black Heather fabric and the response has been incredible thus far. By now, most of you already know our Black Heather looks amazing, but we’re sure you’re wondering how it prints, too.

Our Black Heather is super-soft and made with 99% Airlume combed and ring-spun cotton and 1% poly. To keep the soft hand, we recommend printing with discharge ink. We get asked a lot if you can discharge on our Heather CVC tees, and the answer is yes! Discharge works best on 100% cotton, but it also works great on our Heathers and Triblends, too.

Black Heather Design Contest

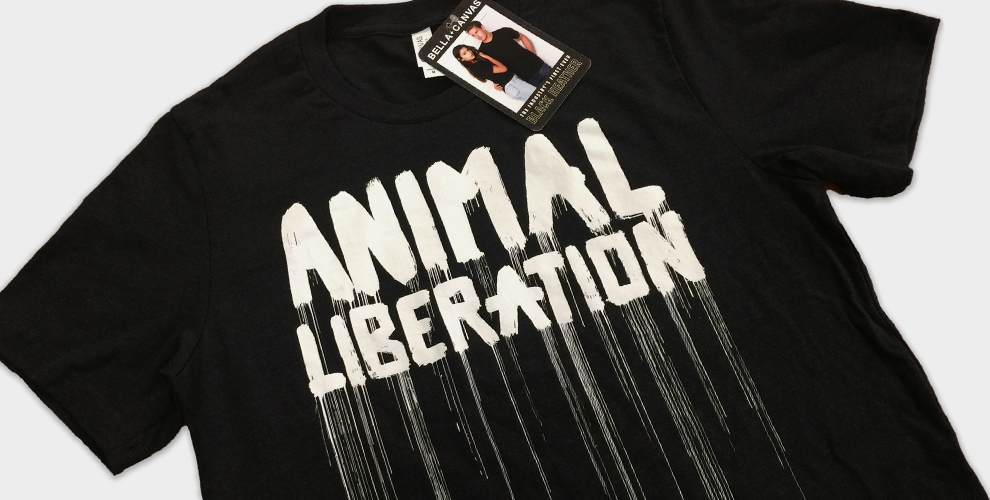

To show you how it’s done, our friends at Deluxe Screen Printing showed us exactly how they printed the awesome graphic they submitted for our Black Heather Design Contest. The print below was printed with white discharge ink and cured for 90 seconds at 320 degrees Fahrenheit. Hopefully this inspires you to print and submit your own design on Instagram (the winner gets a FREE trip to LA!).

The process of discharge printing involves adding discharge solution to water based ink which causes a chemical reaction that extracts the dyes from the fabric. A pure discharge print will result in a natural, light beige or off-white color print once cured – something very close to the natural color of the cotton before it was dyed. In the case of our Black Heather, you’ll see this is a very vibrant white.

There are several reasons our tees take discharge ink so well. The first is that we never over-dye or re-dye our garments. This means the color of our tees is created from the pigment of the yarn itself as opposed to being dyed after it’s sewn. When garments are over-dyed, they dye is typically a more powerful formula (which can cause complications with screen printing as the fabric takes ink in unpredictable ways).

Step-by-Step Discharge Printing Tips

- Getting the accurate weight is crucial when it comes to discharge printing. We highly recommend weighing your containers before adding chemicals. Once finished, record the weights and set the scale to zero before adding in the chemicals.

- Next, add the Discharge Base into your desired container and record the weight.

- Then, add your Activator to the base and be sure it fully dissolves before moving on. Most times, you’ll add 8%, but many people begin at lower percentages so they can watch the color intensify. Bonus tip: only produce what you can use within 24 hours. When the mix sits beyond that, it will start to lose its vibrancy.

- If desired, add a penetrant, which will help the ink penetrate deeper into the fabric. The result? A richer, more vibrant finish.

- Add in a pigment to make colored discharge. 2% is a safe bet, but some manufacturers opt for up to 15% when it comes to whites.

- When it comes to printing, use a heavy stroke to ensure the ink penetrates as deeply as possible into the garment. For a good surface deposit, follow it with a lighter stroke. To prevent the ink from drying the mesh, simply flood the screen before moving on to the next hue. Bonus tip print dark colors early and end with light colors.

- You don’t necessarily need to use a flash between colors, but flashing after the last color will help keep prints brighter.

- Send your project off to the dryer for a final cure!

- Oh, and be sure to pay careful attention to your ink ratios. We highly recommend writing down all ratios, weights, etc., to keep things consistent!

Hope you found these tips helpful! Pick up your Black Heather tees here, and create your own works of art!