Try These 2021 Decoration Trends That Will Set You Apart From the Rest

Retail Inspired Print Placements

All-over Back Print

Behind the Decoration

For this design, the idea was to accentuate the distinctive curved bottom hem on the 3003 tee. We started by printing an oversized graphic which consumes the printable area of the backside of the shirt, extending all the way down to the curved hem. The oversized graphic measures 27” in length which is well beyond the maximum print dimensions achievable by most print shops. So the approach here was to create a single image out of two separate graphic placements.

The first placement covers the upper and mid backside region of the tee. Four distinct colors are printed with soft-hand ink and the shirt is then off-loaded from the press and placed onto the dryer conveyor belt for curing.

The second graphic placement will cover the lower curved portion of the backside of the tee. To do this requires precision loading by the press operator, aided by a laser guide. Additionally, in the design stage, consideration is taken with respect to the contours of the two graphics and the space tolerance between them, to allow for normal variances in operator loading.

Our design is completed by a third graphic placement on the front left chest of the shirt. Total production cost is estimated at anywhere from $3 – $6 per unit, depending on quantity and would wholesale for around $15 – $20. At retail this is a $30 – $40 piece. The final product, inspired from streetwear trends, is definitely a print within the grasp of virtually any printer willing to push beyond perceived limitations.

Full Sleeve Print

Behind The Decoration

On press, the operator employs a nontraditional technique as the garment is side-loaded onto printing platen. Special care is taken here to minimize the stretching of the fabric. The inherent challenge with this technique is the necessity of printing across the grain of the fabric, which leads to difficulty in achieving proper ink coverage. This challenge is mitigated in design with the application of a heavy distressing filter and by utilizing low viscosity soft-hand inks which are able to penetrate the grain.

With the two colors printing in sequence, the wet ink is then flashed to dry prior to off-loading. This last step in the sequence is highly recommended to avoid unintended wet ink transfer in off-loading.

The design is finished with oversized graphics on both sleeves, taking advantage of the expanded print area created by the raglan sleeves.

The end result, achievable by both beginners and advanced printers, is a nod to Japanese street style: bold yet playful and slightly subdued through color scheme and technique. Depending on quantity, production costs are estimated at $6 – $12 per unit. The finished piece would wholesale for around $30 – $40, retailing at $60 – $80 per.

The Wrap Up

How The Garment Color Impacts Photo Print Designs

Powerful Imagery on Vibrant Brights

Behind the Decoration

Powerful imagery makes for epic design and this design, based on an iconic photograph of Dr. Martin Luther King, is certainly no exception. Reproducing the monochromatic photograph begins in pre-press where we start with an advanced Photoshop color separation technique in which fine details and shading are extracted into spot channels and are then output to halftone-based separation files for screen imaging.

Screens are produced, eight in total, using very fine mesh counts which are essential to capturing the high-resolution halftones in the separation files and maintaining detail on press.

On press, screens are carefully aligned following a specified sequence. Multiple layers of black, white, and gray inks are printed to achieve the subtle gradations in the photographic element while a florescent ink is used for the text element.

The final outcome here stuns in both content and delivery. The pairing of the bright background color and monochromatic photograph draw attention and focus on the core iconic image and inspiring message.

This design, best suited for more experienced decorators, is estimated to run $2 – $4 per in production costs with the finished product selling at wholesale for $10 – $15. At retail, this is definitely a $20 – $30 item.

Metallic Inks on Jewel Tones

Behind the Decoration

For our next design, three rich jewel-tone hues in the BELLA+CANVAS line are complimented by three hues of metallic jewel-tone ink and overprinted with a photographic image.

Printing starts with the application of a semi-opaque under-base which is then flashed to dry. Then, a second, highlight under-base is printed which will add a subtle gradation to the finished print.

Next, the metallic jewel-tone ink is printed. This ink, comprised of glitter particles suspended in a clear base which is then tinted with pigments, creates a dramatic shimmer effect.

Lastly, the photographic image is printed with a semi-translucent black ink atop the metallic jewel-tone ink. The translucency of this ink allows the shimmer effect to show through from underneath.

The shimmer effect, combined with the semi-translucent photographic image creates an ethereal quality and brings the print to life. In all, three colorways were created, producing three very distinct looks.

This design presents a certain level of complexity in decoration, but is well within the reach of most printers. Production costs are estimated at $2 – $4 per, with the finished piece selling at wholesale for $10 – $15 per and retailing somewhere between $20 – $30.

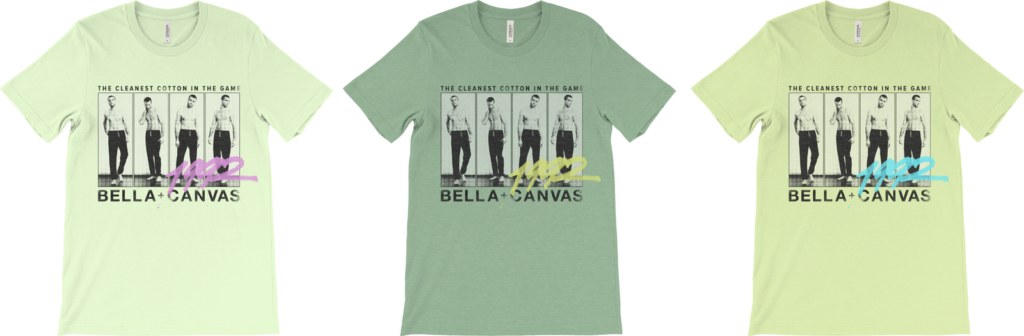

Vintage Look on Shades of Green

Behind the Decoration

Our last design draws inspiration from vintage LP covers and music zines of the 80’s and 90’s. Thoughtful composition and photoshop effects are at the core of producing this genuine look.

Starting with a set of high-res photos from the BELLA+CANVAS catalog, each photo was placed, adjusted for size, and then bounded within a vertical rectangle. The high quality composite was then virtually destroyed through a filter to create the vintage look. Text and graffiti elements were added and then a distressed effect was applied to the entire graphic.

This design, is very forgiving due to the heavy distressed effect and is achievable by most printers. Production costs are estimated at $2 – $4 per unit, with the finished piece selling at wholesale for $10 – $15 and retailing somewhere between $20 – $30.

The Wrap Up

Experimental Etching Technique on Fleece

Sueded Fleece

Behind the Decoration

This design is based around a textile etching technique, where a specialized laser literally burns an image into the fabric. Because various substrates respond differently based on their fiber content, we decided to work with two unique fleece fabrications from the BELLA+CANVAS line to see how they would respond.

First, our sueded fleece fabrication in Heather Oatmeal. After some initial tests where the intensity and speed of the laser were adjusted to optimize definition without burning the fabric, we were able to achieve a subtle yet sophisticated de-bossed effect into the plush substrate.

Sponge Fleece

Behind the Decoration

Second, our sponge fleece fabrication in Poppy: After making some additional adjustments, gradually increasing the intensity, we were able to again create a clean and subtle look, but this time without the de-bossed effect. In the end, two unique design variants were created, both exhibiting a high-end retail aesthetic.

This design is recommended only for more established decorators possessing the specialized equipment necessary to accomplish the laser etching technique. Estimated production costs are $3 – $6 per unit, with the finished piece selling at wholesale for $30 – $40 and retailing somewhere between $60 – $80.

The Wrap Up

Featured Print Shop

Learn more

Catch up with our 2021 Trend Report here.

Check out our color forecasting article! Click here.

Have you seen our shop by color feature? Learn more here.

Want to learn more about BELLA+CANVAS? Click here.

Subscribe to our YouTube channel! Click here.

1 Comments

Lisa

I like the textile etching example and background color examples.